What to see inside Shirley Windmill

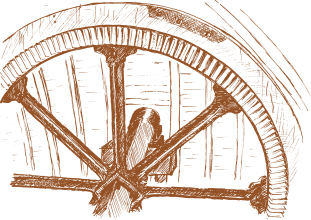

The Brake Wheel

The Dust Floor is the highest working floor, and can be looked upon as the “engine

room” of the mill, where the power of the wind was converted to useable power to

drive all the machinery. From high up inside the Cap, there is a good view of the

machinery at this level. The sails outside the Cap turned the inclined Windshaft,

which extends from the front to the back of the Cap. Made of cast iron, it holds

the sails firmly at the Poll End, just outside the front of the Cap. As the sails

turned, the Windshaft turned.

Fixed to the Windshaft, just inside the front of the Cap, is the Brake Wheel, also

of cast iron. This is 2.8m (9ft 4in) in diameter, and against its rim is a wooden

band brake around almost all its circumference, which gives the Brake Wheel its

name. The brake can be operated by a long oak lever, either from inside the Cap

or from the ground, to stop the mill turning. The brake wheel has 172 wooden teeth,

or Cogs, to engage with and turn a horizontal wheel below it, called the Wallower,

which is fixed to the top of the vertical cast iron Drive Shaft. This extends down

through the floor to drive the machinery below.

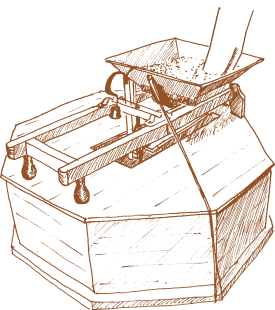

The Stone Furniture

At Shirley Windmill there are two sets of Millstones. Each set comprises two stones:

the Bed Stone is the lower one, which remained stationary, whilst the upper, Runner

Stone, turned on top of it. One of the sets now has a recently restored and remade

set of Stone Furniture, which consists mainly of a wooden box around the Millstones,

called the Stonecase, with its lid, and the Feed Gear on top.

The grain was fed

down from the bins on the floor above into the Hopper, and trickled out of a hole

in the bottom into an inclined channel, called the Shoe, which was shaken by the

multi-armed spindle known as the Damsel, so that there was a steady flow of grain

to the stones, without clogging. Grain trickled steadily from the shoe into the

hole in the centre (the “eye”) of the turning Runner Stone, to be ground into meal

between it and the stationary Bed Stone below.

The Runner Stone is visible through

the hole in the lid of the Stonecase, which is also sometimes known as a Vat or

Tun. It is an “underdrift” or “underdriven” stone, meaning that it was driven from

below. The grinding surfaces of the stones have a series of grooves, or Furrows,

with flat areas between called Lands. The size, shape and weight of the stones can

more easily be appreciated by looking at the other Runner Stone, which has been

stood up against the wall, on the opposite side of the room.

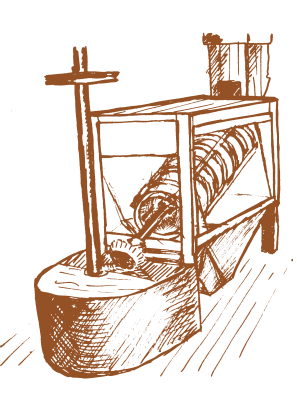

The Dressing Machine

Millstones produce meal — that is, ground whole grain, including bran. Some or all of the bran, the ground-up husk of the grain,

must be removed from the meal to

produce a white flour. This was done by sieving the meal in the Dressing

Machine, which can be seen on the Spout Floor. This is basically an inclined cylindrical

wire sieve, through which the meal was fed from above. A series of rotating brushes

inside brushed the flour through the very fine sieve mesh, leaving the bran behind.

The flour and bran were thus separated, and could be fed down into different sacks

on the ground floor below. The Dressing Machine at Shirley Windmill was, like all

the other machinery, wind powered, using an auxiliary geared drive.

The Ground Floor was probably used for storage, and possibly a workshop. This contains

a grain-cleaning machine, or Smutter, similar to the Dressing Machine on the floor

above, and was for sieving out any dust or fine grit before the grain was taken

up through the mill to be ground. Also on this floor is the millers Balance, used

to weigh the sacks of flour, which all had to be accounted for very carefully. The

canvas chutes from the Dressing Machine above are visible on this floor, some to

take flour, some to take bran, into the waiting sacks.

There are several instructive models and displays on this floor, together with a

continuously running video about windmills and their operation, so visitors who

are unable to climb the stairs have plenty to interest them.

What to see outside the windmill